高温下的双重挑战:列车人力巡检的困境与机器人巡检破局

2025年夏季,全国多地持续突破40℃高温,对于铁路检修工作而言,列车检修运用库如同炙烤的火炉,让铁路检修工作人员在检修列车时面临严峻考验:①、需要在闷热的车底沟道连续长时间检修作业,中暑和伤病风险骤增。②、在高温和照明度不佳环境中长时间检修作业大大降低检修效率和检修精准率。

人力巡检的“烤”验:效率与安全的双重挑战

库内热蓄积效应:

大型钢结构库房在强烈日照下吸热显著,加之通风效率受限,库内空气温度常远高于室外,形成闷热、不流通的“蒸笼”环境,员工长期在这样环境中工作会大量出汗影响操作、积热环境中金属工具易烫手、防护服于高温场景下透气问题无法解决,加剧闷热不适感。

高温下列车智能巡检机器人的“巡检破局 ”

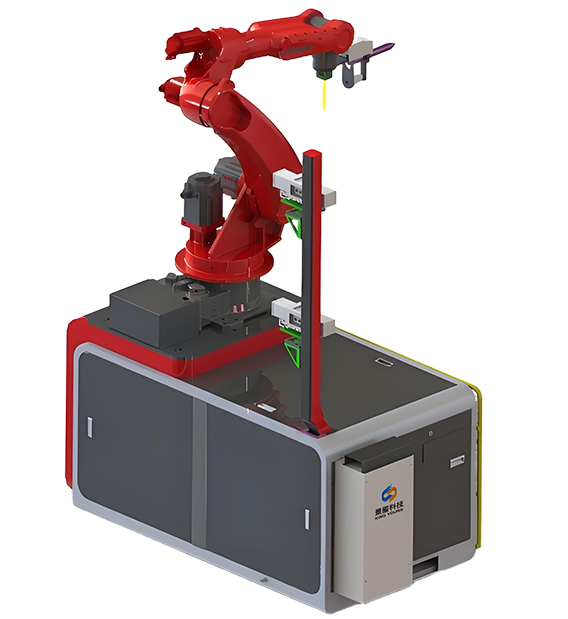

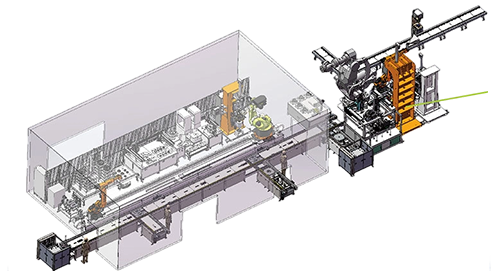

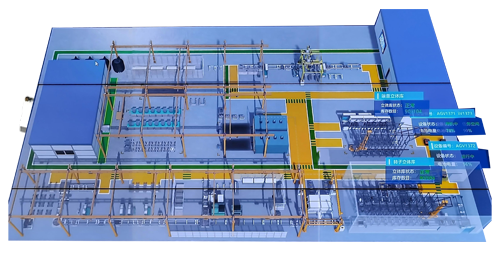

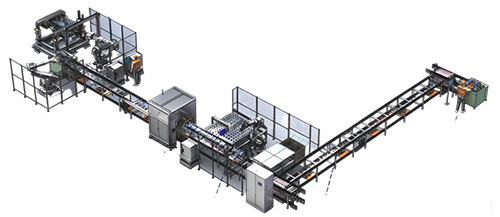

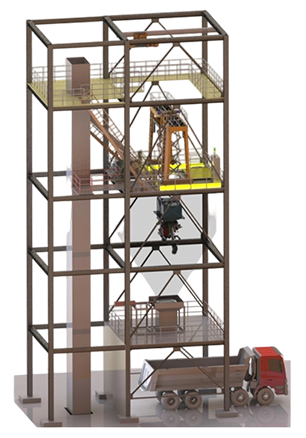

面对严峻的检修环境和苛刻的检修结果要求,景曜研发的列车智能巡检机器人能在高温闷热的环境下对列车进行快速、高效的全方位巡检。相比于人工巡检而言机器人巡检具有很明显的优势:①、智能化巡检机器人能长时间耐得住高温闷热的检修环境;②、先进的视觉检修技术能在低暗的车底和视角不佳的区域高效巡检;③、智能AI能够排查潜在隐患;④、巡检报告机器人本体实时生成避免数据误差和减少数据分析时间。

与此同时,搭载高精度结构光相机与AI视觉的巡检机器人正成为新解决方案——它们不仅可在人工难以忍受的高温下稳定运行,而且单次任务时间超5小时,可执行跨股道车底车侧连续巡检,且识别准确率≥99%。

景曜列车智能机器人巡检的“冷”优势:

全时域、高精度作业

环境适应性:

采用对流及接触式热传导方式,保障机器人于高温情况下内部电气元件运行正常,最高可于环境温度55℃运行,可在高温下列车检修库长时间持续巡检工作。

7*24h随时待命:

机器人凭借自动充电功能以及大容量电池,支持长快速巡检+快速返航充电闭环,支持全天候全时段待命,执行各项需求任务。

巡检成本效益:

以某线路24全列19运4检1备运营模式计算,单台机器人每晚可执行3~4台以上全列车辆的无电巡检作业,最多可节省替代2~3名工作人员,提高检车作业效率情况下,极大减少人员巡检作业压力,减低人员安排成本。智能化分析 通过结构光相机与阵列式快扫模块,机器人可采用停车精扫+不停车快扫方式快速完成任务,全列车底+车侧巡检时间可达1小时以内,极大提高巡检速度。

在铁路飞速发展的时代,安全是铁路运行的基础。在钢铁脉络中穿行的景曜智能列车巡检机器人,正以精准的"数字之眼"守护着亿万旅客的出行安全。它们替代人员钻入狭小的车底间隙,在酷热的环境中持续工作,如同永不疲倦的哨兵将“铁路人”从高危作业环境中解放出来同时景曜智能巡检机器人每一次精准检测,都是对"人民铁路为人民"承诺的智能化诠释。

图片来源网络