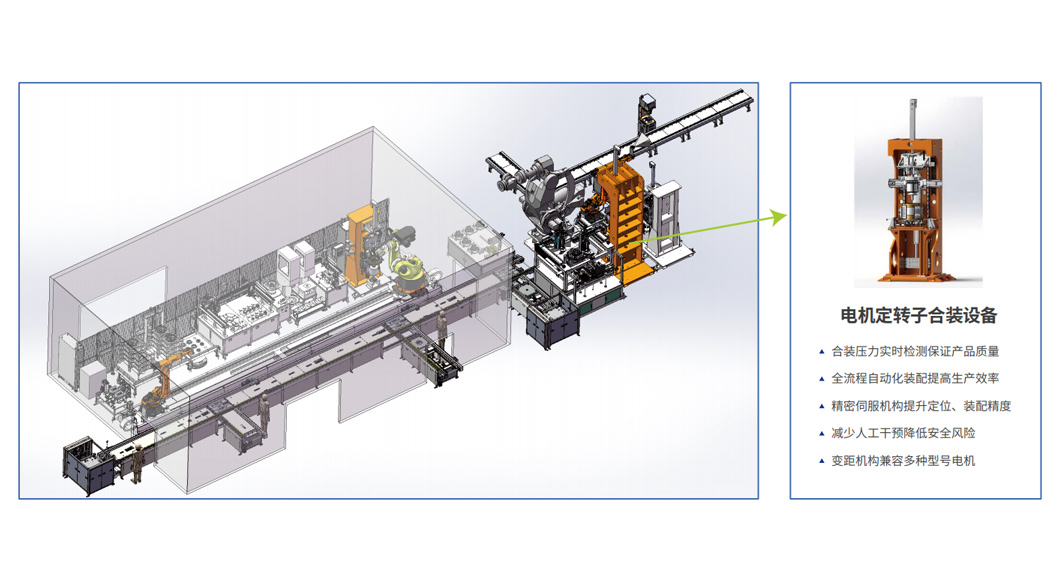

解决方案

由轴承注脂压装、转子装配、定子装配、电机总装和电机试验5个单元组成,实现动车、城轨、永磁电机的自动化生产要求。

轴承加脂压装单元,可兼容20多种产品型号,具有自动换型、适用性广泛的优势。

电机定转子合装单元,采用立式合装方式,兼容异步电机和永磁电机,在行业内具有领先意义。

由轴承注脂压装、转子装配、定子装配、电机总装和电机试验5个单元组成,实现动车、城轨、永磁电机的自动化生产要求。

轴承加脂压装单元,可兼容20多种产品型号,具有自动换型、适用性广泛的优势。

电机定转子合装单元,采用立式合装方式,兼容异步电机和永磁电机,在行业内具有领先意义。

配件自动上料

自动注脂

自动称重

自动压装

自动检测

端盖/转子合装

端盖/定子合装

定转子合装

自动螺栓拧紧

游隙检测

全流程信息上传