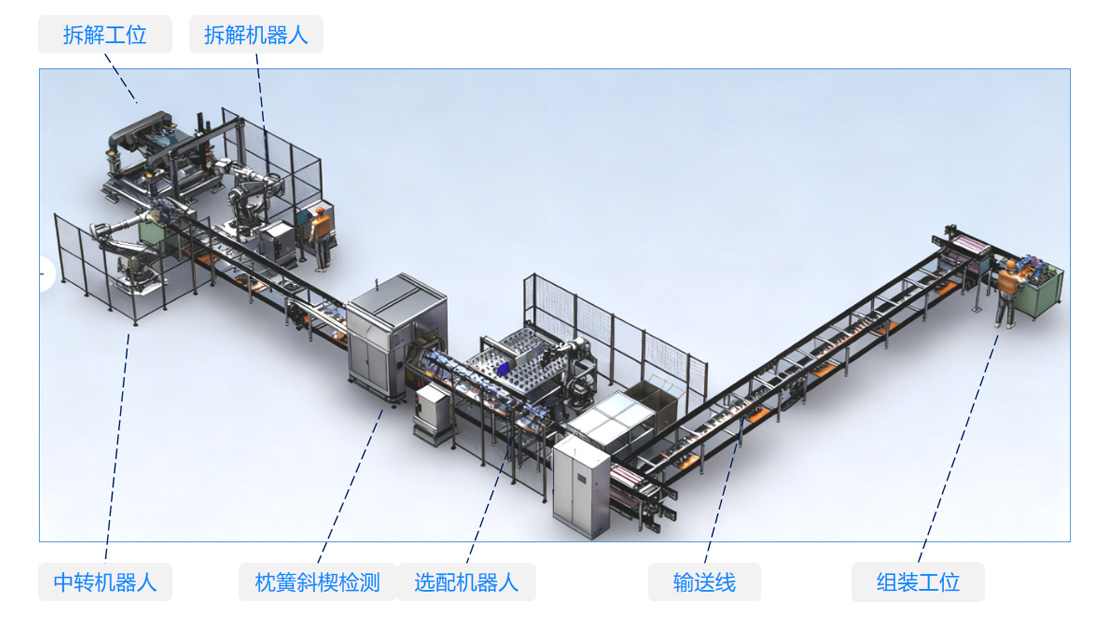

解决方案

针对货车转向架进行枕簧斜楔的自动拆解/输送/检测/选配作业;

集枕簧斜楔的拆解、检测、分拣、选配功能为一体的自动化智能装备,应用3D视觉检测和工业机器人技术;

实现枕簧斜楔的自动拆解、智能检测选配,检测准确度超过98%,检修效率相较人工提高200%;

针对货车转向架进行枕簧斜楔的自动拆解/输送/检测/选配作业;

集枕簧斜楔的拆解、检测、分拣、选配功能为一体的自动化智能装备,应用3D视觉检测和工业机器人技术;

实现枕簧斜楔的自动拆解、智能检测选配,检测准确度超过98%,检修效率相较人工提高200%;

适用工件:K6、K2转向架

拆解效率:≤5min/转向架

≤5min/转向架:视觉检测【3D线扫激光】

枕簧检测指标:内外簧自由高

枕簧检测精度:±0.2mm

斜楔检测方式:视觉检测【3D结构光】

斜楔检测指标:斜楔磨耗、斜楔表面缺陷

斜楔检测精度:±0.2mm

选配规则:铁路货车厂修/段修规程