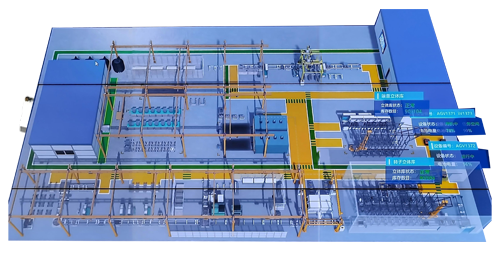

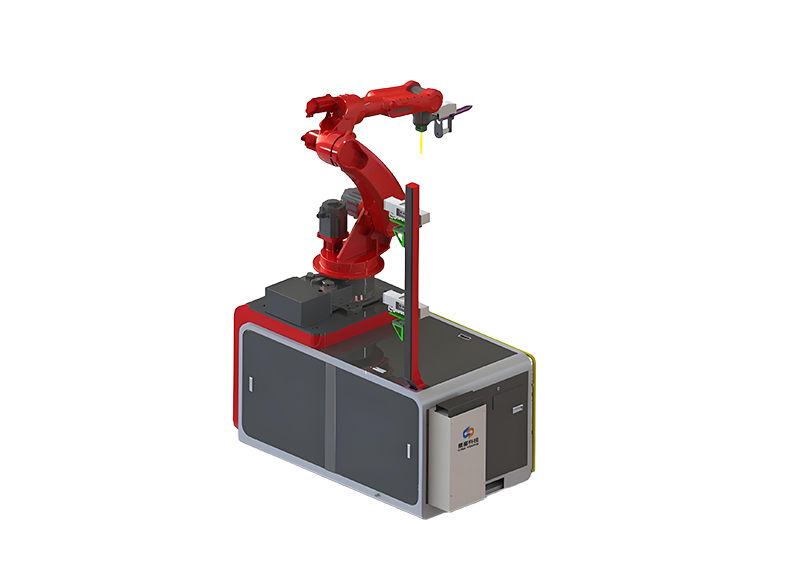

自定义切割工艺控制

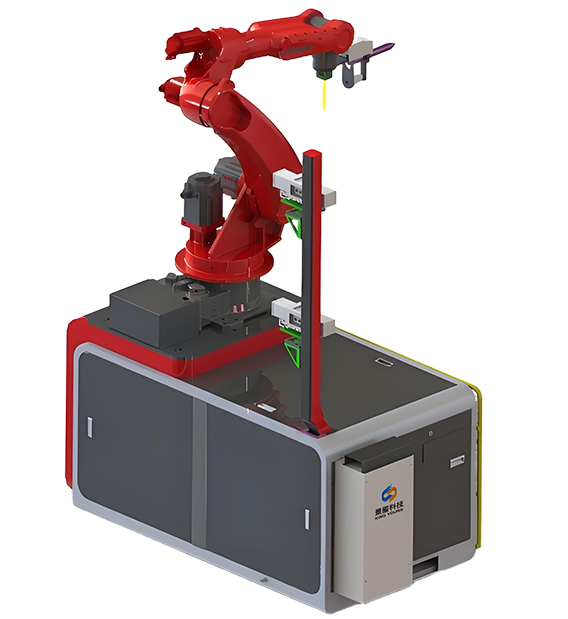

主要功能

高精度3D视觉

智能路径避障

精准切割

智能机械臂运动控制

智能路径规划

优势

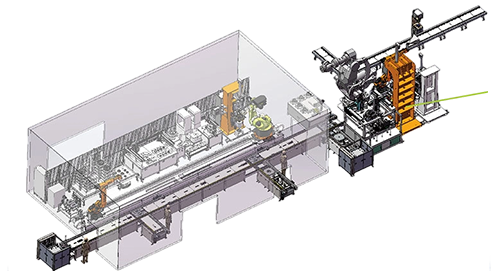

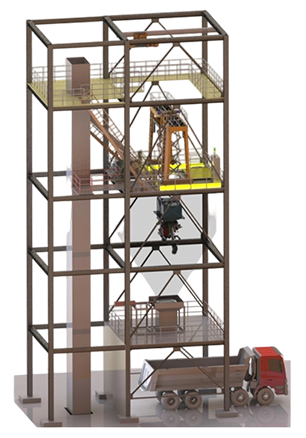

适应性强

可适用铁路货车主流C70、C64车型。

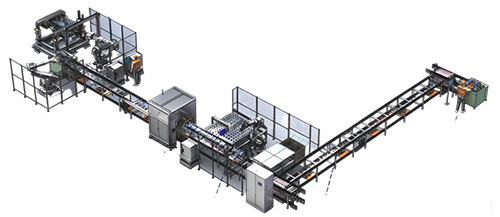

效率高

切割铁路货车整车时长在25min左右。

精度高

切割精度在切割工艺要求±3mm误差范围内,达到精切要求。