列车缺陷识别

主要功能

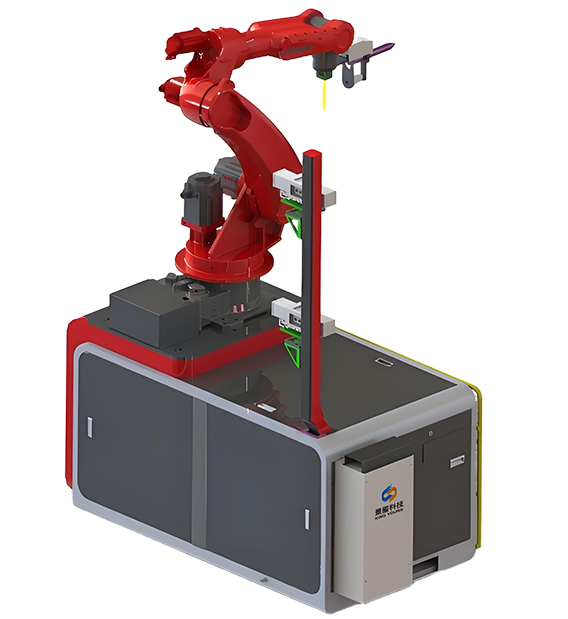

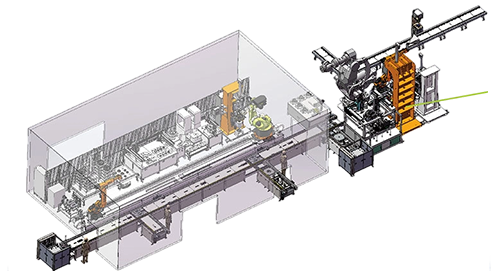

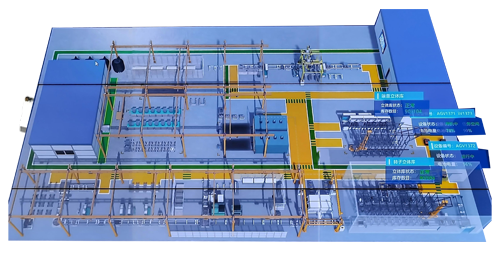

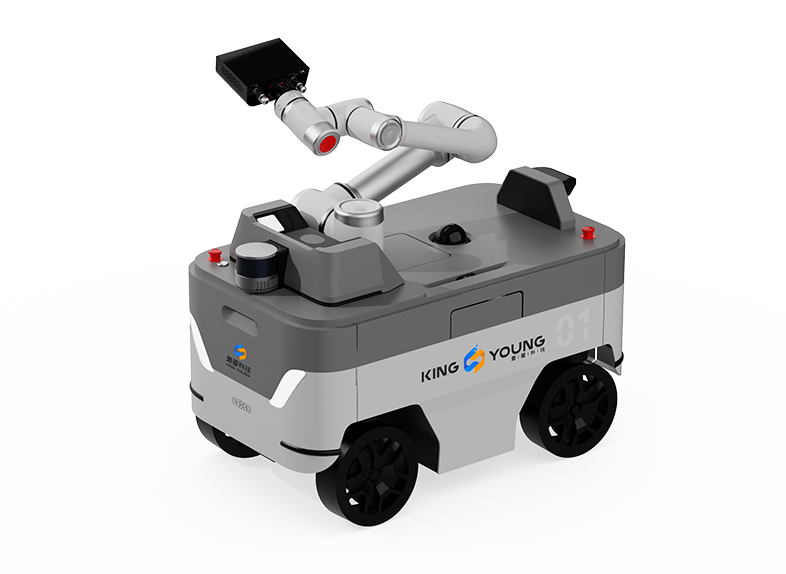

自主导航定位

AI大模型应用

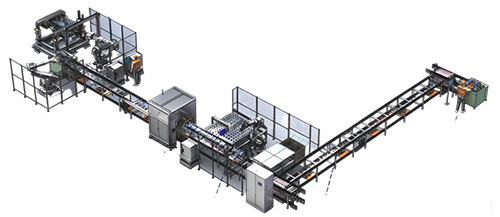

多机器人协同

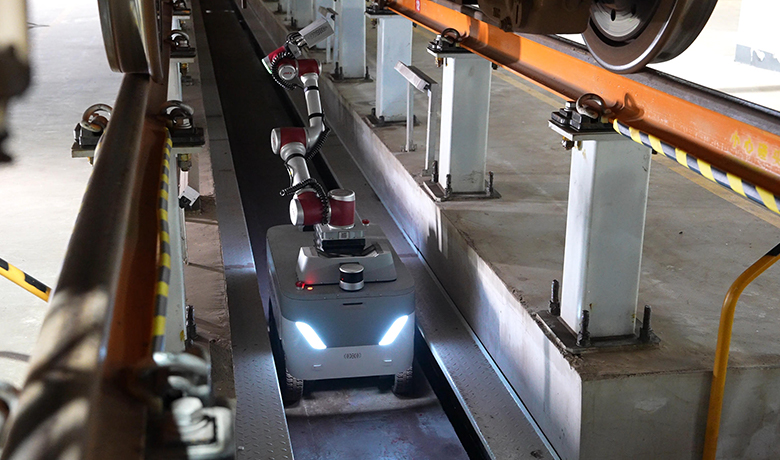

狭窄场景适应

多模态组件选配

优势

场地适应性强

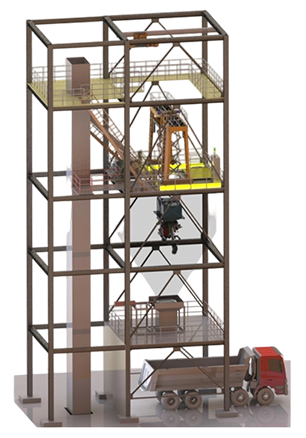

• 运动方式:四转四驱,25°爬坡,无需土建改造轻松跨轨。

• 越障能力:50mm高线缆、140mm宽沟槽库内越障。

• 进沟方式:兼容沟道端部、立柱间两种入沟方式。

检项覆盖全

• 覆盖车钩、轮对、牵引装置等核心一、二级部件。

• 人工日检项综合覆盖率可达93%以上。

识别能力强

• 缺陷综合检测正检率:95%以上,其中松动类、丢失类,异物可达98%以上。

• 具体组件识别:

• 松动部件:≥98%

• 缺失部件:≥99%

• 异物检测:≥95%

• 误报率:≤3‰

巡检效率高

• 6编组地铁列车(车底及两侧),拍照数量:1200+。

• 总体识别项点:10000+。

• 检测时长:车底及两侧控制在55分钟左右。

部署时间短

• 无需场地土建改造,1个月内完成产品现场部署,具备采图识别能力。

• 控制软件模块化、流程设计自动化、部署效率高。

定位精度高

• 列车定位精度:±3mm,可以精准定位列车车轴部位。

• 导航定位精度:±5mm,行驶过程中停车精度高,行业领先。

• 行业领先的定位进度带来精准的识别效果和检测效率。