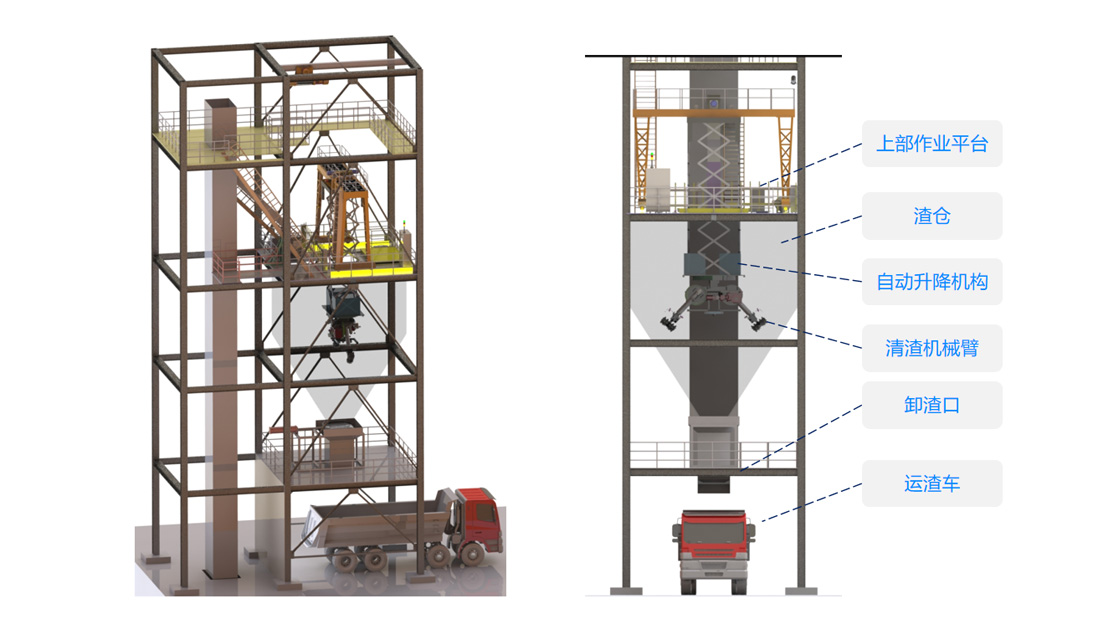

解决方案

智能自主清渣系统由智能多关节机械臂、多关节控制自主清渣执行装置、多向调节垂直升降系统、三维激光扫描系统等构成,结 合高速率通信网络架构设计,以拟人手持工具形式对渣仓内壁进行自主清渣作业,保持内部下料的顺畅性,实现远程无人化、智能化 清渣作业。

智能自主清渣系统由智能多关节机械臂、多关节控制自主清渣执行装置、多向调节垂直升降系统、三维激光扫描系统等构成,结 合高速率通信网络架构设计,以拟人手持工具形式对渣仓内壁进行自主清渣作业,保持内部下料的顺畅性,实现远程无人化、智能化 清渣作业。

工作温度:-30℃至60℃

工作湿度:相对湿度≤90%

短时间耐温:≥+70℃

清渣效率:不低于90%

清渣升降机构行程:不小于8m

范围覆盖:渣仓内部上下的需清渣部位

重复定位精度:≤±1cm

清渣机构:高压水枪、高压吹气、液压镟挖破碎头等

3D视觉相机:精度不低于0.1mm,配置防护外壳

相机分辨率:不低于1080P,自清洁

煤渣高度检测传感器:测量范围≥15m